I still say sizing the nose will greatly help in accuracy.

After you PC or tumble lube you resize the bullet for consistency right. A bore riding bullet is mostly supported by the bore riding section to give it stability so the nose doesn't slump. Not that I will at these speeds. So if the main body is benefitted by resizing for consistency so will resizing the bore riding section for consistency. I would increase the thickness of the PC and then resize the body and the nose (bore riding section) to properly fit that guns barrel. All this will aide in accuracy but your accuracy is not too bad as it is already. Or maybe I'm just out of my mind. Who knows these days!

266 grain cast bullet, the Dolomite special

Moderators: gds, bakerjw, renegade, bamachem

- Dolomite_Supafly

- Silent But Deadly

- Posts: 3017

- Joined: Fri Oct 30, 2009 7:03 am

- Location: East Tennessee

- Contact:

Re: 266 grain cast bullet, the Dolomite special

Sizing the nose is probably not possible from a manufacturing standpoint. Might work great for the individual but probably won't work well for a mass produced bullet. I caution against sizing the nose of this bullet because that will change how it is supposed to work. There is a very specific reason why the nose is the way it is and sizing it will negatively affect that.xdmalder wrote:I still say sizing the nose will greatly help in accuracy.

After you PC or tumble lube you resize the bullet for consistency right. A bore riding bullet is mostly supported by the bore riding section to give it stability so the nose doesn't slump. Not that I will at these speeds. So if the main body is benefitted by resizing for consistency so will resizing the bore riding section for consistency. I would increase the thickness of the PC and then resize the body and the nose (bore riding section) to properly fit that guns barrel. All this will aide in accuracy but your accuracy is not too bad as it is already. Or maybe I'm just out of my mind. Who knows these days!

The coating that will be used in production is very consistent. It is not a one coat coating that can clump or go on thicker than we want. Because of that the manufacturer can very precisely add dimension to get to the proper size. As long as the bullet is consistent, which it will be, adding the coating will not affect the bullet's performance in a negative way. Some coatings go on thicker or are blotchy. When you have an inconsistent coating thickness it will negatively affect accuracy but also stability. The blotchy coating will move the softer lead so if you have a big blotch of coating on the side of the bullet it will make the bullet unbalanced after sizing. And the fast twists we see in 300 Blackout will only make it worse. So the choice of coatings is just as important as the bullet design.

Another consideration I took account was the case capacity, specifically how much was left for the powder after the bullet is seated. The space is optimized for the powders typically used in the 300 Blackout. That is because we all know that case fill and powder position can affect accuracy. So this bullet was designed to give you less space so your powders will burn more completely but also more consistently. It is that consistency that leads to accuracy. This is one reason why these seem to be shooting as well as they are.

Care was taken to try to make this bullet work in a widest variety of chambers possible. Because it was designed specifically for the 300 Blackout is also very forgiving when working up accurate loads. Even without load development we are seeing positive results and those results will only get better as people use the bullet.

I welcome any questions.

If there is anyone who would like to try some prototypes please let me know.

WWW.thegunmilitia.com

Come join the militia!

Come join the militia!

Re: 266 grain cast bullet, the Dolomite special

That all makes sense. I did not realize this was going to be a production bullet.

Re: 266 grain cast bullet, the Dolomite special

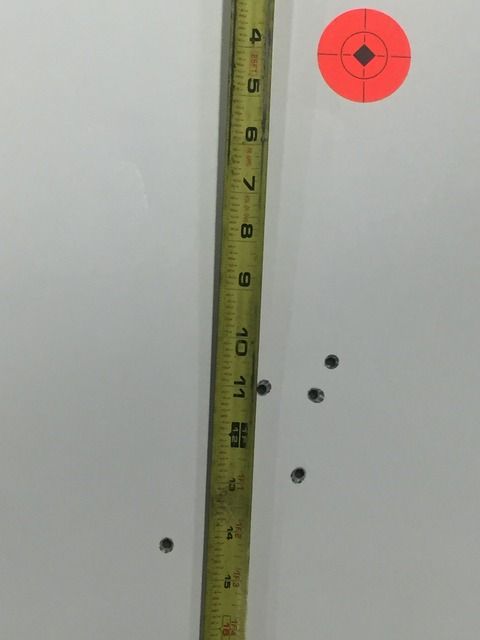

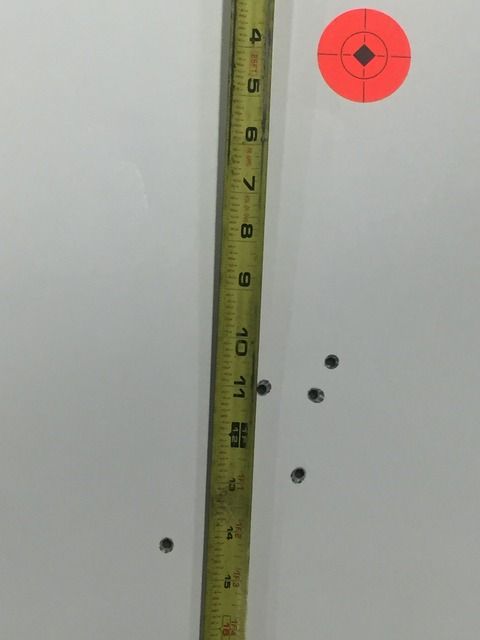

A little more time with these this weekend, took them out to the 100 yard mark. Results were mixed. Still looking for the the extreme edges of the bullets performance, so I shot one five shot group from two rifles, both AR's.

An 18" 1/10 twist and a 8" 1/5 twist. I had trouble with the 8" last time out at 50 yards so moved the scope, spent some trigger time, and shot a 3/4" group at 50 cutting the last group by more than 50%.

Targets shot seated from a bipod, no rear support.

This was from the 8", 1/5 shot with a 50 yard zero. About an 8" drop. Four shots comfortably minute of clay and who knows what happened #5. Staring to show a little bit of wobble. I am actually pretty happy with this as a starting place for load development, the ES needs to be tightened and the stock needs at least a bag for any serious accuracy evaluation.

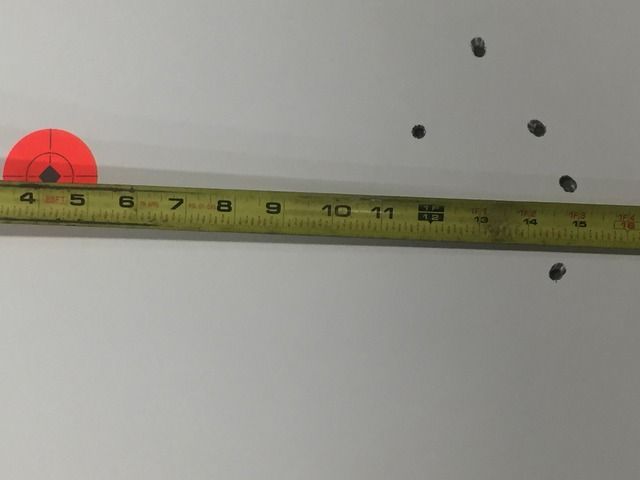

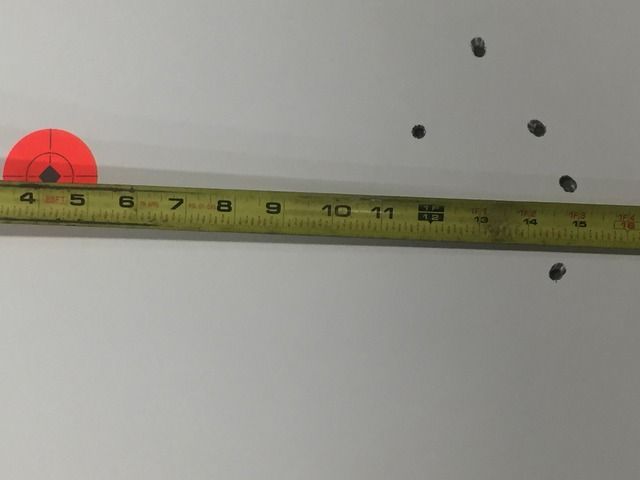

Here's where things fell apart. We knew going in that a 1/10 twist would be a stretch, but it printed so well at 50, I had to stretch it some.

Same 50 yard zero, velocity within 10 fps of the other rifle, but 4" more drop and some pretty ragged holes. Good example of how a poor spin rate and wobble rob you of distance.

Overall it seems like a pretty good bullet. With proper load development and an honest effort at accuracy I think you could easily cut 1/2"-1" off group size at 100 yards. As it is, with basically no load refinement, to be able to walk out and hit clays at 100 yards 80% of the time, carrying nothing more than your rifle to the range is acceptable plinking for me.

An 18" 1/10 twist and a 8" 1/5 twist. I had trouble with the 8" last time out at 50 yards so moved the scope, spent some trigger time, and shot a 3/4" group at 50 cutting the last group by more than 50%.

Targets shot seated from a bipod, no rear support.

This was from the 8", 1/5 shot with a 50 yard zero. About an 8" drop. Four shots comfortably minute of clay and who knows what happened #5. Staring to show a little bit of wobble. I am actually pretty happy with this as a starting place for load development, the ES needs to be tightened and the stock needs at least a bag for any serious accuracy evaluation.

Here's where things fell apart. We knew going in that a 1/10 twist would be a stretch, but it printed so well at 50, I had to stretch it some.

Same 50 yard zero, velocity within 10 fps of the other rifle, but 4" more drop and some pretty ragged holes. Good example of how a poor spin rate and wobble rob you of distance.

Overall it seems like a pretty good bullet. With proper load development and an honest effort at accuracy I think you could easily cut 1/2"-1" off group size at 100 yards. As it is, with basically no load refinement, to be able to walk out and hit clays at 100 yards 80% of the time, carrying nothing more than your rifle to the range is acceptable plinking for me.

300 Blackout, not just for sub-sonics.

- Dolomite_Supafly

- Silent But Deadly

- Posts: 3017

- Joined: Fri Oct 30, 2009 7:03 am

- Location: East Tennessee

- Contact:

Re: 266 grain cast bullet, the Dolomite special

We are in pre production status now. We are making sure the machines are casting the bullets to spec and they are perfect. Automated casting machines are being used to ensure lot to lot consistency and the highest quality. By automating the process we have taken the human out of the equation and that means a more consistent bullet and a consistent bullet will be an accurate bullet. Their alloy is certified 92-6-2 to ensure lot to lot consistency and quality. We are also using a more consistent coating, Hi-Tek. So if you order 1,000 bullets today you can be guaranteed to get the same exact bullet the next time you place an order.

The bullets themselves are deep red in color and look great. I will try to get some high quality photos up before too much longer.

I am sending out test batches of these pre production bullet this week. As long as these bullets continue to perform the production molds will be ordered and these will for sale by June at ACME Bullet Company.

Even if you are not interested in buying these I strongly suggest you check them out because they do make some great bullets and in many calibers. They also sell components like brass as well as their bullet casting alloy as ingots. ACME also supports the shooting sports by sponsoring shooting teams as well as helping out other organizations. They really are charitable. The owner, and his wife, are great people who understand it is their customers who keep them in business so they strive to keep their customers happy. They are ALWAYS available if you have a question or a concern and go out of their way to ensure every customer is a happy customer.

If you are a manufacturer of loaded ammunition and would like to use this 265 grain bullet in your loaded ammunition please contact me.

The bullets themselves are deep red in color and look great. I will try to get some high quality photos up before too much longer.

I am sending out test batches of these pre production bullet this week. As long as these bullets continue to perform the production molds will be ordered and these will for sale by June at ACME Bullet Company.

Even if you are not interested in buying these I strongly suggest you check them out because they do make some great bullets and in many calibers. They also sell components like brass as well as their bullet casting alloy as ingots. ACME also supports the shooting sports by sponsoring shooting teams as well as helping out other organizations. They really are charitable. The owner, and his wife, are great people who understand it is their customers who keep them in business so they strive to keep their customers happy. They are ALWAYS available if you have a question or a concern and go out of their way to ensure every customer is a happy customer.

If you are a manufacturer of loaded ammunition and would like to use this 265 grain bullet in your loaded ammunition please contact me.

WWW.thegunmilitia.com

Come join the militia!

Come join the militia!

Re: 266 grain cast bullet, the Dolomite special

Have been shooting some of the bullets cast myself from test mold.

Today's group's ran around 1 inch at 55 yards using Imr4227 in my Delta Co. Arms 16 inch upper.

It has shot as good as any cast bullet I shoot and with the heavier weight it's easier to find sub-sonic loads that worked with a 16 inch barrel carbine gas system.

They shot accurately from a 8 and 10 inch also.

Rem bolt gun shoots them very well.

Inch or less every time.

I like the heavy bullet and look forward to using it more.

Today's group's ran around 1 inch at 55 yards using Imr4227 in my Delta Co. Arms 16 inch upper.

It has shot as good as any cast bullet I shoot and with the heavier weight it's easier to find sub-sonic loads that worked with a 16 inch barrel carbine gas system.

They shot accurately from a 8 and 10 inch also.

Rem bolt gun shoots them very well.

Inch or less every time.

I like the heavy bullet and look forward to using it more.

- Dolomite_Supafly

- Silent But Deadly

- Posts: 3017

- Joined: Fri Oct 30, 2009 7:03 am

- Location: East Tennessee

- Contact:

Re: 266 grain cast bullet, the Dolomite special

First, I would like to thank you for your time, energy and supplies needed to test this bullet. A few years ago I would have thought it was not possible to get this kind of accuracy, and reliability, from a subsonic cast bullet but we are seeing it with this bullet. Time and time again people are seeing similar results without any sort of load development. I cannot wait to see the results once we really start fine tuning everything.45r wrote:Have been shooting some of the bullets cast myself from test mold.

Today's group's ran around 1 inch at 55 yards using Imr4227 in my Delta Co. Arms 16 inch upper.

It has shot as good as any cast bullet I shoot and with the heavier weight it's easier to find sub-sonic loads that worked with a 16 inch barrel carbine gas system.

They shot accurately from a 8 and 10 inch also.

Rem bolt gun shoots them very well.

Inch or less every time.

I like the heavy bullet and look forward to using it more.

WWW.thegunmilitia.com

Come join the militia!

Come join the militia!

Re: 266 grain cast bullet, the Dolomite special

First go with the final version was an exercise in making as many mistakes loading as possible while loading and back up why you should not do them on paper.

Dots are 1" for reference.

Shot a 50 yards

Group on the right is what happens when you grab a bunch of random brass. I could feel the difference in neck tension while seating the bullets. Top shot is cold clean bore. These were loaded at 2.110, the shortest I have ever seated them and the worst group I have ever had.

Group on the left seated at 2.145", this length is max length for my chamber in a Model 7. I also changed to matching headstamps. The hole on the bottom right shaved a little when seating while seating. I actually shaved two rounds before getting things adjusted correctly. After the flyer instead of shooting the second one I pulled the bullet. It's below.

Shaving the coating is a bit of a problem, but cutting the edge of the base a sure way to have a flyer.

Been fighting weather for a good shooting session, but again a lot of promise for very little work. Hope to hear from some others.

Dots are 1" for reference.

Shot a 50 yards

Group on the right is what happens when you grab a bunch of random brass. I could feel the difference in neck tension while seating the bullets. Top shot is cold clean bore. These were loaded at 2.110, the shortest I have ever seated them and the worst group I have ever had.

Group on the left seated at 2.145", this length is max length for my chamber in a Model 7. I also changed to matching headstamps. The hole on the bottom right shaved a little when seating while seating. I actually shaved two rounds before getting things adjusted correctly. After the flyer instead of shooting the second one I pulled the bullet. It's below.

Shaving the coating is a bit of a problem, but cutting the edge of the base a sure way to have a flyer.

Been fighting weather for a good shooting session, but again a lot of promise for very little work. Hope to hear from some others.

Last edited by dellet on Tue May 09, 2017 2:13 pm, edited 1 time in total.

300 Blackout, not just for sub-sonics.

Re: 266 grain cast bullet, the Dolomite special

These bullets are the only cast bullet to shoot good in my fussy 8.3 inch barrel and I'll probably be getting a mold when available.

The test mold I used seemed to have a more rounded nose at the top but it looked like version 3 had been wrote on the side.

That version you have pictured looks just as good or better.

I wish this bullet was around when I bought my Noe mold.

I'm getting real good accuracy and it hits harder than the 311247.

They took out the back of my crumb rubber bullet trap.

The test mold I used seemed to have a more rounded nose at the top but it looked like version 3 had been wrote on the side.

That version you have pictured looks just as good or better.

I wish this bullet was around when I bought my Noe mold.

I'm getting real good accuracy and it hits harder than the 311247.

They took out the back of my crumb rubber bullet trap.

Re: 266 grain cast bullet, the Dolomite special

Are you ever going to offer molds? For us roll your own's?

Phil

Phil

Who is online

Users browsing this forum: No registered users and 59 guests