HELP! AR Leading issues

Posted: Tue Oct 13, 2020 4:25 am

Hey, all,

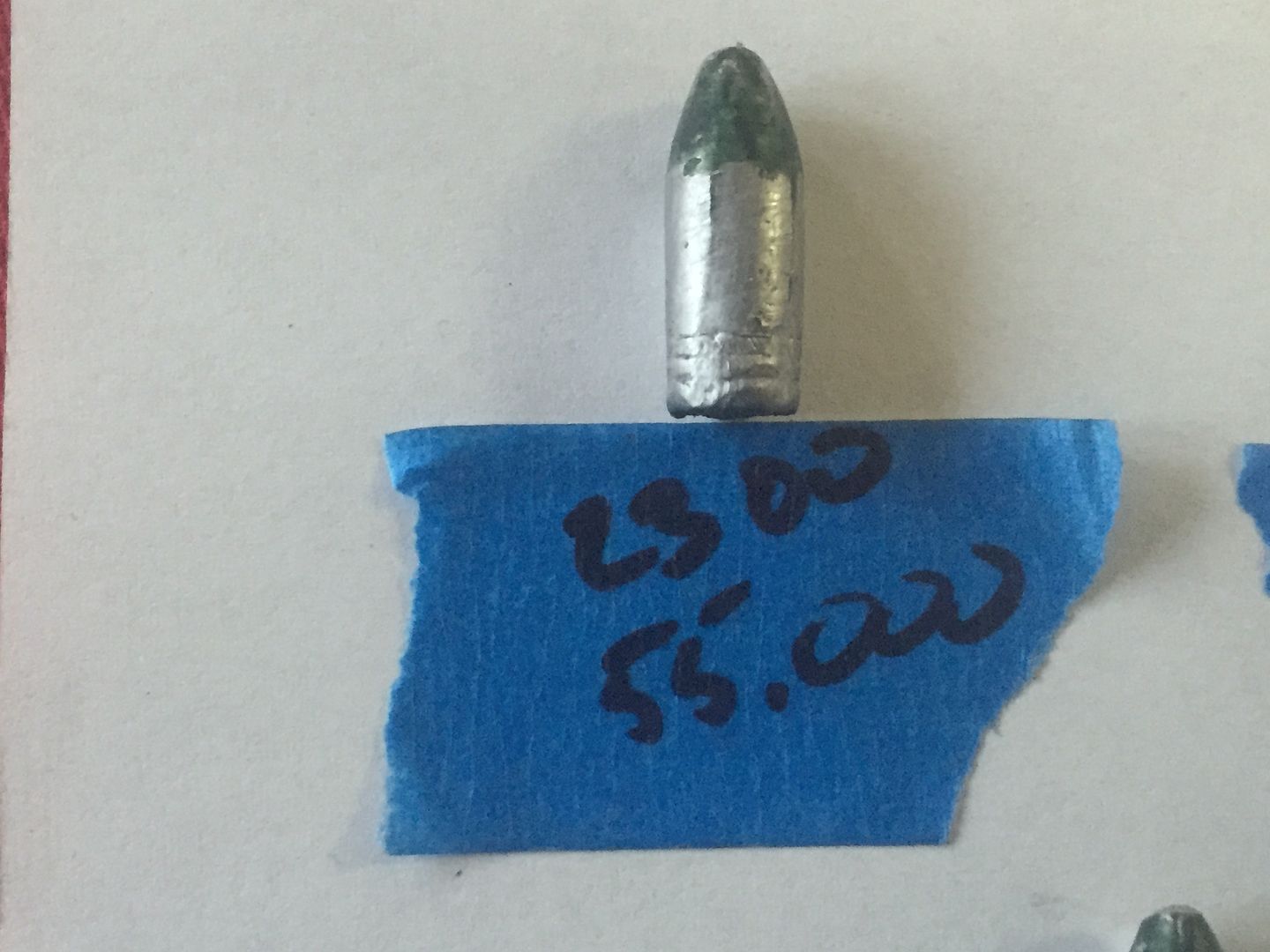

I need some help. I have been shooting the Lee 312-155 bullets for a few months with GC and have been getting lead marks on my AR flash suppressor. I am also getting a ton of lead around the bolt and the three gas washers. The barrel doesn't show much leading at all as I use HiTek coating. I was originally sizing to .309 but thought maybe the bullets were still too big for my AR-15. I got a .311 sizing die and it still is leading the rifle. I think it may be the lead is simply too soft as I use straight wheel weights and range lead. Is that the issue? What can I add to make it harder? I do quench as I cast. I'm using the rounds for short range plinking 25-50yds. I recently downloaded a lead excel formula, but don't know how hard I should make the bullets on the Brinel scale. I'm using 17 gr of LilGun to get 1972 fps at 2.00 oal as that has been the most accurate load. Again help!!! Thanks.

Tattoo

I need some help. I have been shooting the Lee 312-155 bullets for a few months with GC and have been getting lead marks on my AR flash suppressor. I am also getting a ton of lead around the bolt and the three gas washers. The barrel doesn't show much leading at all as I use HiTek coating. I was originally sizing to .309 but thought maybe the bullets were still too big for my AR-15. I got a .311 sizing die and it still is leading the rifle. I think it may be the lead is simply too soft as I use straight wheel weights and range lead. Is that the issue? What can I add to make it harder? I do quench as I cast. I'm using the rounds for short range plinking 25-50yds. I recently downloaded a lead excel formula, but don't know how hard I should make the bullets on the Brinel scale. I'm using 17 gr of LilGun to get 1972 fps at 2.00 oal as that has been the most accurate load. Again help!!! Thanks.

Tattoo