Okay now I'm confused. The decap/expander screws in through the top of the sizing die with a little base and a lock ring. If I run a case up into the die with the expander installed, there's no way to pull the case out with the expander still inside the case. It's locked to the die.dellet wrote: ↑Mon Jul 27, 2020 6:35 pm I'm sorry I was not clear on instructions.

Feed the expander down into the case, then remove the case with the stem flopping around inside and gauge it. Then feed the expander back into the die as it was before and remove the case as normal.

I read through the rest of the thread again, are you still having the gap between shell holder and ram when sizing?

Issue with forming 300 BLK from 223

Moderators: gds, bakerjw, renegade, bamachem

Re: Issue with forming 300 BLK from 223

Re: Issue with forming 300 BLK from 223

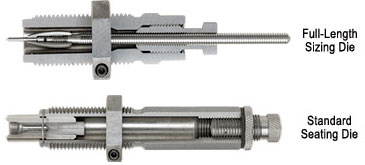

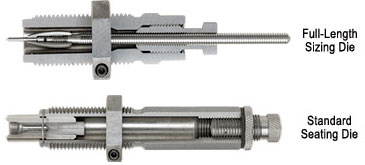

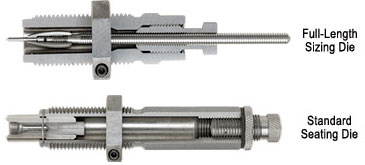

Is this your die, RCBS?

You should be able unscrew both the lock ring then the insert that threads into the die off the top of the expander and have that fall out the bottom.

You should be able unscrew both the lock ring then the insert that threads into the die off the top of the expander and have that fall out the bottom.

300 Blackout, not just for sub-sonics.

Re: Issue with forming 300 BLK from 223

Ahhh okay I understand now. So this is hilarious...I ran a case into the die w/ expander installed, then I unscrewed the lock ring and insert from the expander part itself, and I was only able to get the assembly out of the press by removing the shellholder. The expander part is so long that it's still inside the die (or even the spot for the die if removed) when the ram is at the bottom. Now that it's off the press, the decap pin is protruding below the hole in the shell plate, so I cannot remove the decap/expander part. There's simply no way to do it. Pics: https://imgur.com/a/TtVIg0X

Re: Issue with forming 300 BLK from 223

Didn’t think about that, some pins are pretty long. I guess if you really wanted to, you could remove the pin. I generally do and decap separate from sizing so didn’t think a out it.madmosche wrote: ↑Mon Jul 27, 2020 9:35 pmAhhh okay I understand now. So this is hilarious...I ran a case into the die w/ expander installed, then I unscrewed the lock ring and insert from the expander part itself, and I was only able to get the assembly out of the press by removing the shellholder. The expander part is so long that it's still inside the die (or even the spot for the die if removed) when the ram is at the bottom. Now that it's off the press, the decap pin is protruding below the hole in the shell plate, so I cannot remove the decap/expander part. There's simply no way to do it. Pics: https://imgur.com/a/TtVIg0X

300 Blackout, not just for sub-sonics.

Re: Issue with forming 300 BLK from 223

cwlongshot wrote: ↑Mon Jul 27, 2020 8:17 pm Madmosche & SIG220:

MY REPLY ABOUT LEE DIES WAS TO HUNTON35!

No worries guys we are trying ta help ya here!

CW

I am still following along, I figure there is always something to learn in a thread that keeps going awhile.

I am probably a little "anal" (that looks nasty) about my case prep when going to convert a 223 into 300BO.

I resize them in 223 first (which deprimes them), then I cut them and then clean the burrs out inside and out and form them in my 300BO dies.

If I cut to the right length, they will form out at app. 1.363 plus or minus. I am set up to trim but don't like doing it.

BTW, for some odd reason or personal makeup, I enjoy reloading.....almost as much as I enjoy shooting!

Also, some of my cases when processed have a little bell to them, but once I seat the projectile you would have never known.

Re: Issue with forming 300 BLK from 223

Yeah I could cut off the decap pin, but first I'll wait to see what RCBS says. I don't want to start taking sandpaper and dremel tools to my dies until I'm 100% sure the problem isn't somewhere else, or just a defect in the die/expander. I appreciate the input and help from everyone!

Re: Issue with forming 300 BLK from 223

Or you could unscrew the expander from the stem and remove it so you can put it back later. That way when it breaks you’ll know how to do it. Often an extra is in the box with the dies.madmosche wrote: ↑Mon Jul 27, 2020 10:55 pmYeah I could cut off the decap pin, but first I'll wait to see what RCBS says. I don't want to start taking sandpaper and dremel tools to my dies until I'm 100% sure the problem isn't somewhere else, or just a defect in the die/expander. I appreciate the input and help from everyone!

300 Blackout, not just for sub-sonics.

Re: Issue with forming 300 BLK from 223

When you try and size a case with no expander that is when it flares the neck? Do you put the locknut back in? Maybe you are threading it down a bit too far as it looks that can flare the mouth if it hits it. Put some black sharpie on the bottom of the locknut to see if it is hitting the case. It should bring it back to shape but maybe it has enough springback without the expander to control the expansion.

"Freedom is the sure possession of those alone who have the courage to defend it."

~Pericles~

~Pericles~

Re: Issue with forming 300 BLK from 223

Yes, without the expander it bells the case mouth. I am not putting the lock nut/insert back in. I can see right down into the die as I’m sizing/forming, the case mouth is not hitting anything.Omega wrote: ↑Tue Jul 28, 2020 11:57 am When you try and size a case with no expander that is when it flares the neck? Do you put the locknut back in? Maybe you are threading it down a bit too far as it looks that can flare the mouth if it hits it. Put some black sharpie on the bottom of the locknut to see if it is hitting the case. It should bring it back to shape but maybe it has enough springback without the expander to control the expansion.

Unrelated question: on a 300 BLK AR upper (or any AR I guess), how hard should you have to push on the back of the BCG to manually chamber a case?

Re: Issue with forming 300 BLK from 223

It shouldn't be too difficult, if it is, one way to check is to drop the round into the barrel by hand, it should drop right into the chamber with little effort. Using the sharpie method (or Dykem) you can check where it is hitting, or at least where the friction points are.madmosche wrote: ↑Tue Jul 28, 2020 12:07 pm Yes, without the expander it bells the case mouth. I am not putting the lock nut/insert back in. I can see right down into the die as I’m sizing/forming, the case mouth is not hitting anything.

Unrelated question: on a 300 BLK AR upper (or any AR I guess), how hard should you have to push on the back of the BCG to manually chamber a case?

Not my pic but it shows how it's done.

This is why I like the Sheridan cutaway gauge, it's easy to see where it is hitting.

"Freedom is the sure possession of those alone who have the courage to defend it."

~Pericles~

~Pericles~

Who is online

Users browsing this forum: AlinMi, Bing [Bot] and 85 guests